All posts by admin

BBV Newsletter – February – March 2023

BBV Newsletter – December 2022 – January 2023

BBV Newsletter – October – November 2022

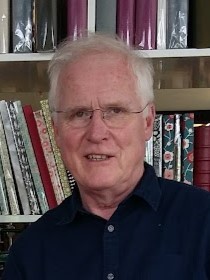

Rob Shepherd – Obituary

It is with great sadness that we have to report the death of Rob Shepherd, Managing Director of Shepherds Bookbinders Ltd and co-founder of Bound by Veterans, who died on 13th August after a long illness. He set up his bookbinding business in 1988 and not only became widely known and respected amongst the bookbinding community but was also passionate about training and spared no effort in trying novel training methods and developing opportunities for learning craft bookbinding.

It is with great sadness that we have to report the death of Rob Shepherd, Managing Director of Shepherds Bookbinders Ltd and co-founder of Bound by Veterans, who died on 13th August after a long illness. He set up his bookbinding business in 1988 and not only became widely known and respected amongst the bookbinding community but was also passionate about training and spared no effort in trying novel training methods and developing opportunities for learning craft bookbinding.

In 2011 he co-founded Bound by Veterans, known initially as The Wiltshire Barn Project, and as its prime sponsor helped it reach charitable status a year later. He then helped place Bound by Veterans on a secure footing by persuading the City & Guilds Institute to reinstate bookbinding onto its list of heritage crafts and provided the means by which we are now able to award these internationally recognised City & Guilds qualifications to Veterans. In recent years he was a catalyst for the creation of the Queen’s Bindery Apprenticeship Scheme and pivotal in the development of national Apprenticeship standards for bookbinding, although perhaps behind it all he was inspired by a keen desire to find Veterans from his “special” charity who might graduate from classes at the Daffodil Barn to a full-blown commercial apprenticeship in the bookbinding trade.

He promoted the charity tirelessly through the Worshipful Company of Stationers, of which he was a Liveryman, and the many other links he had made in the bookbinding and commercial world. He gave us a solid financial start and mapped out a development programme that we follow today. It combines craft training with the therapeutic support for which this charity has become synonymous, and produces a regime that promotes confidence, self-esteem and mental well-being. We will miss his advice and influence but, above all, will miss a real gentleman who supported us with charm, dedication and determination.

If you wish to donate, please use the button below.